News from the Productronica trade fair

The SEREC team at the Productronica 2025 stand

We would like to thank all the visitors who attended our demonstrations.

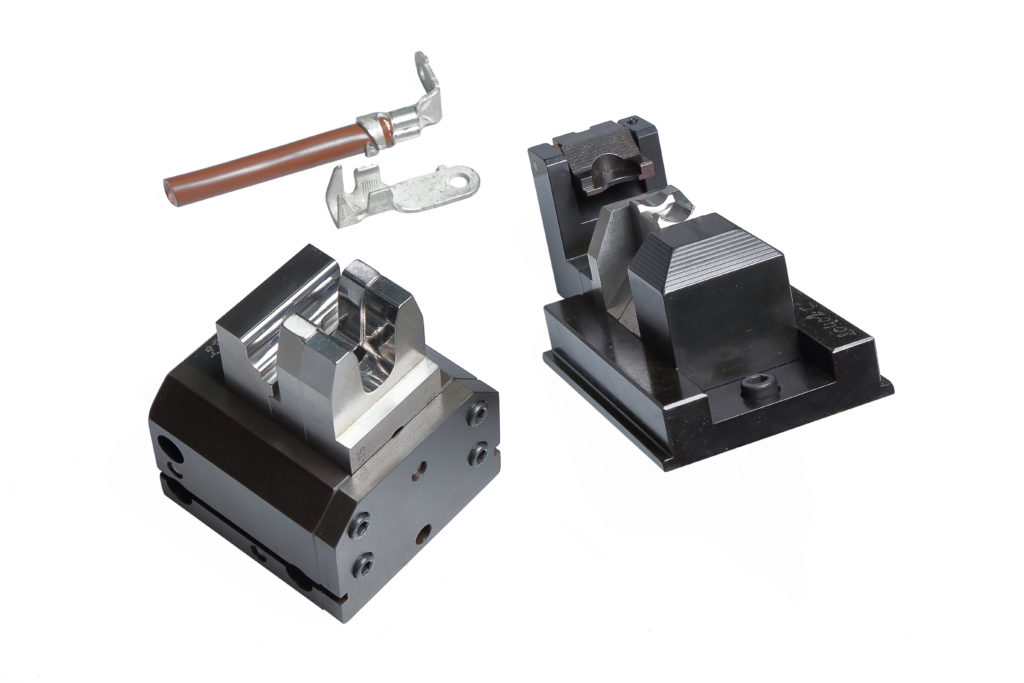

Crimping

TRP Standard Serec tools

- Standard crimping tool

- Tool for bending and crimping in a single operation

- Crimping tool for band terminals with pneumatic feeding

- Terminal band cutting and forming tool

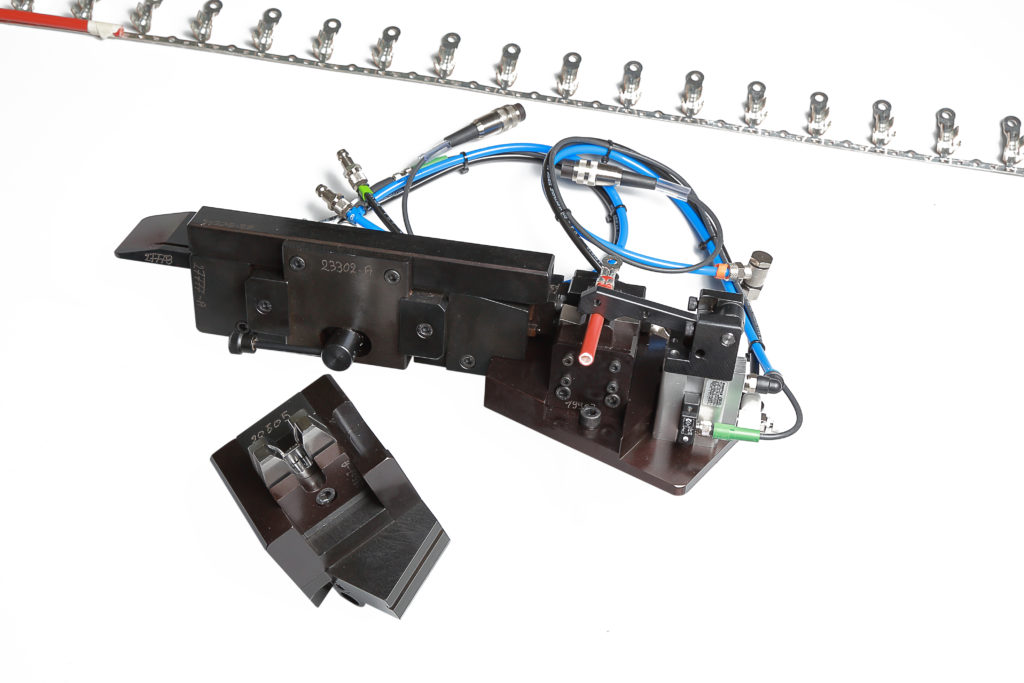

SEREC S91400 pneumatique crimping press

- Crimping press on complete workstation

- Cycle secure by TwinSAFE Beckhoff

- Safety ROSS 5/2 double valves CrossMirror

- Optional Crimp force monitoring

Open crimping tool description sheet

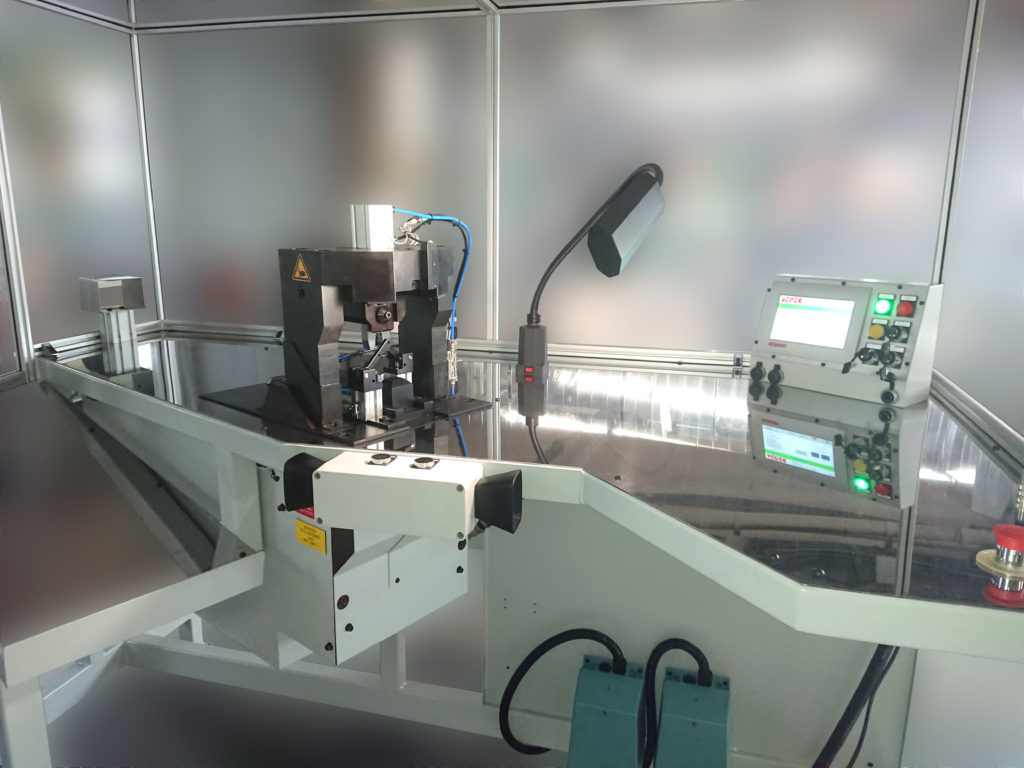

RADIAL CRIMPING (SRC)

- Radial crimping machine (SRC)

- Fast crimping cycle (≃ 3s)

- Multi faceted crimping

- 6 punches

- 8 punches

- Punches position controled by servomotor

- Forty recipes with different crimping mode

- Optional crimp force monitoring

- Cycle secured by TwinSAFE Beckhoff

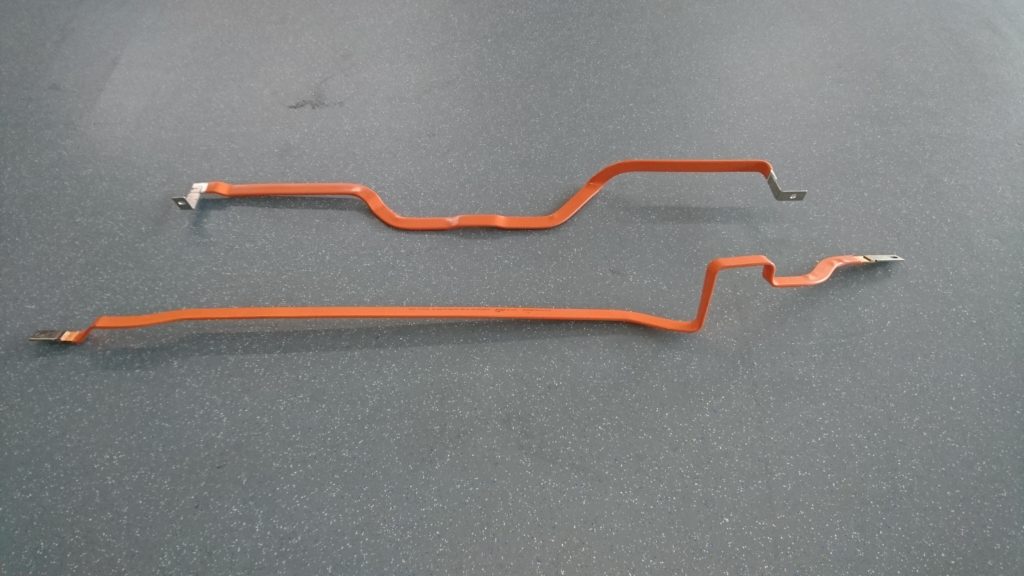

Bending

Busbar bending modul

Internal flat cable for battery packs (electric vehicles)

- Standalone numerical bending module for XY bending

- Z-Bending module with shape forming die with pneumatic movement

Turntable transfer for copper cables with processing of both ends

- Fitting of heat-shrinkable sleeves

- Stripping

- Crimping

- Hot air shrink tubing

- Cable turnaround

- Processing the second side of the cable

Automatic machine

- Stand-alone machine such as

- Special crimping

- Stripping

- Aluminium cable crimping

- Milling aluminium cable

- Conveyor transfer machine with successive operations.

- Cable cutting

- Stripping

- Crimping

- Fitting of heat-shrinkable sleeves

- Hot air shrink tubing

- Evacuation on conveyor belt

Linear transfer of wrapped aluminium cables with processing of both ends

- Fitting aluminium sleeves

- Radial crimping of sleeves

- Milling of sleeve ends

- Welding on terminal (KUKA machine)

- Transition to the second conveyor

- same operations on the other side