EXPERTISE AND KNOW-HOW

SEREC designs and manufactures crimping tools since 1954.

Today, SEREC is specialised in the following activities:

- Crimping of heavy-duty cables (from 16 to 150 mm²)

- Aluminium cable processing (radial crimping and milling)

- Processing of flat cables (copper or aluminium)

- Flat cables cutting

- Bending of flat cables, in particular busbars for automotive battery packs

- Automatic transfer line for cutting, stripping and crimping cables

Open SEREC company description sheet

ETUDE

STUDY ON 3D CAD SOFTWARE (TOPSOLID) AND 3D CAD SOFTWARE (MEDUSA)

Since 1992, SEREC has been using CAD to study and design its tools and machines.

From 1992 to 2010, MEDUSA was used for all 2D and 3D studies..

Since 2010, TOPSOLID has been used as a 3D CAD design tool combined with powerful CAM software that allows us to launch manufacturing directly on our CNC machining and wire EDM machine.

PRODUCTION

PRODUCTION MANAGEMENT THROUGH ERP

SEREC uses an ERP-type IT management tool that, based on tool or machine nomenclature, allows :

- Component stock management

- Management of finished parts inventory and pre-machined material blocks

- Editing manufacturing sheets

- Editing the stock removal form

- Creation of all supplier orders for missing components

- Creating the material orders required for manufacturing the parts launched into production

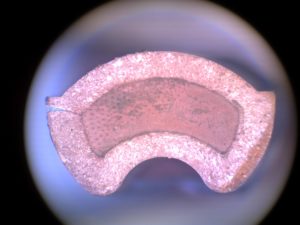

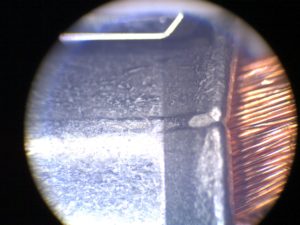

ANALYSIS BY METALLOGRAPHIC SECTION OF CRIMPING

SEREC uses metallographic cutting management software

SEREC also uses an algorithm to pre-calculate crimping specifications.

- The software calculates the compression ratio.

- The software calculates the surface area of holes remaining between strands.